Membrane filtration – a versatile suite of technologies, but no panacea – Greg Foley outlines the application of membrane filtration in an engineering context, focusing on ultrafiltration and microfiltration processess

A membrane is physical barrier through which pure solvent can pass while other molecules or particles are retained. Most membranes are made from synthetic polymers, although in recent times, interest in the use of ceramic materials has increased. These tend to be very robust and can withstand harsh operating and cleaning conditions.

For ultrafiltration (UF) and microfiltration (MF) applications, polysulphones are often used. Other materials that are used commercially include polyvinylidenefluoride (PVDF), polyacrylonitrile (PAN) and polypropylene (PP). Reverse osmosis (RO) membranes are often made of polyamide while nanofiltration (NF) membranes are constructed from a variety of polymers, including polysulphone, polyimide, and ceramic materials.

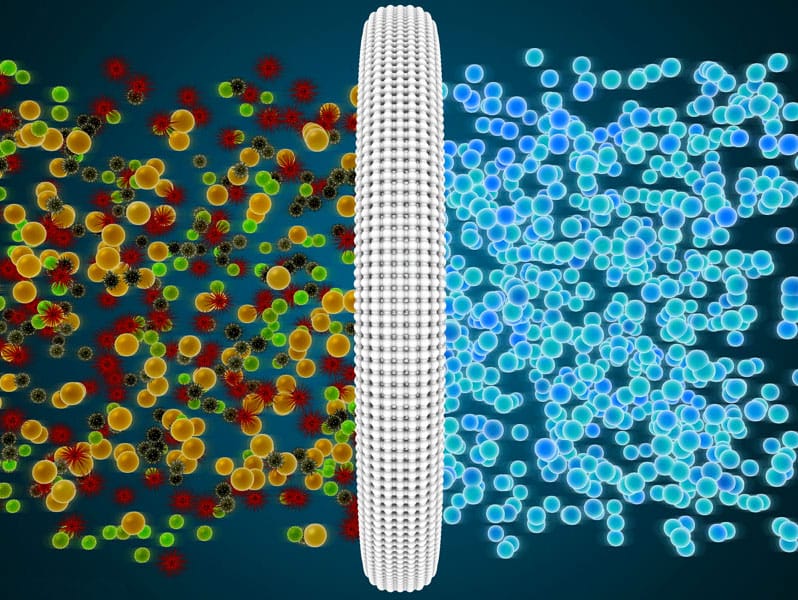

In the case of UF and MF, the semi-permeability of the membrane is largely a result of the relative sizes of the solute/particles and the membrane pores. This is what is known as a sieving mechanism. Solute retention is a little different in RO and is largely determined by charge effects. The RO membrane can be thought of as a matrix through which solvent and solute diffuse at different rates. NF occupies one of those awkward transitions zones that are often encountered in engineering and it has characteristics of both UF and RO. Solute retention is a highly complex process, involving both size and charge effects.

MF is the filtration of suspensions containing particles that are generally less than 10 μm in diameter. For particles greater in size than this, the ‘micro’ prefix is dropped and it is generally understood that filtration is done in dead-end mode rather than the crossflow mode typically used in membrane filtration operations (Fig.1).

Figure 1 Dead-end and Crossflow filtration

UF is essentially the filtration of solutions of high molecular weight molecules. NF, by contrast, involves the filtration of solutions of molecules such as peptides, antibiotics and other compounds with molecular weights in the range 100–1000 g/mol. In RO, the solutions being filtered contain very small ionic species such as Na+ and Cl- ions. It is worth mentioning in passing that there are situations where one might use a membrane in a filtration process for which it is not actually designed. For example, it would not be unheard of to use a UF membrane to filter a microbial suspension because such a choice may lead to better long-term performance. Whether this is UF or MF is a debatable point, but it is probably more sensible to classify it as UF.

Click here for the full article.